About the Books

In essence, commonplace books are personal miscellanies. Since at least the middle ages, people have relied upon these blank books to compile and organize their daily experiences and thoughts. Inspired by this idea, these books seek to continue this tradition by providing an ideal place for you to record things as valuable as family recipes, inspiring passages, and plein air sketches, to those as commonplace as a to-do list or a passing thought.

Our commonplace books are all individually crafted using traditional materials, sound structures, and time tested techniques. Each and every book is made by Brien from start to finish. Though historically inspired, these books are not models of historic bindings, and often incorporate unique blends of structures and decorations that span multiple centuries and continents.

A commonplace book bound in black goatskin with both gold and bind tooling. The lozenge shaped decoration in the middle of the cover is executed using four different tools.

Sheets are folded down into sections for sewing with a bone folder, which is a polished piece of bone specially shaped for the purpose. These sections are more or less the final size of the book.

To begin, large sheets of German mould-made paper are first cut and folded into sections, forming the basic units of a bound book. These sections are put in a press over night to consolidate them into a compact and solid entity. They are next arranged in a neat stack, and the folds are punched with an awl to mark where the cords will go.

Next and one of the most iconic steps in the binding process is sewing. Each and every section is hand sewn on linen cords anchored to a late-19th century frame whose design dates to at least to the 12th century and still fits the bill today. Though tedious, a tight and even sewing is perhaps the single most important aspect of a book's function and durability.

Sewing on six raised cords. These cords are key components of the finished book's structure and aesthetic, as they will eventually result in the raised bands on the spine of the finished volume.

From left to right: glued up, rounded, and backed. The small grooves that result from backing are the joints that eventually receive the boards.

Once sewn a thin layer of glue is applied to the spine that unifies and helps it to retain its form while it is rounded and backed with a hammer. Rounding helps keep the spine from becoming concave with use, while backing creates grooves that accommodate the thickness of the cover boards.

At this point, the ends of the cords are laced through holes poked in the boards, and the boards are pulled snug against the joint. The ends of the cords are snipped close but not flush with the boards, and are pasted and hammered in place.

Two commonplace books with 17th century inspired double-holed lacing patterns. This image depicts the cords after they are trimmed to their final length but before they are pasted and hammered flat.

Here is a detail of the business end of the plough. The blade is depicted mid-cut as it makes a pass along the half-trimmed head, or top edge, of the book. As the wooden screw is turned (just visible at the top of the image), the blade progresses across the width of the book less than a millimeter each pass, trimming just a few pages at time but resulting in a perfectly smooth edge.

Once dry the book edges are trimmed and decorated, whether with color, precious metal, or sprinkling. Trimming is accomplished with a lying press and plough, which is a tool specially designed for the purpose that, like the sewing frame, has been around for centuries, and still gives the smoothest edge.

After edge work come the endbands, also commonly called headbands. Endbands are little decorated cores that reside at either end of the spine. On commonplace books, they consist of colored silk that is wound around a short length of linen cord directly to the spine of the book. Aside from being a beautiful decorative element, endbands also eventually support the leather caps that turn in over the spine.

An assortment of silk endbands and stained and sprinkled edges.

Five commonplace books with freshly lined spines. The raised sewing visible between the linings will eventually become the iconic raised bands that give well-bound books their distinctive aesthetic.

As the penultimate step before covering, strips of handmade paper that help provide additional support to the sewing are adhered to the spine. It is an important reinforcement, but care must be taken not to over-line the spine, as this will restrict the book's ability to open and potentially damage the sewing along the way.

Now the book is ready to be covered. The leather, either calf or goat, is cut from the skin and and edges are pared with a razor sharp knife to facilitate turning the leather in over the board edges during covering. Freshly cooked wheat starch paste is applied to the suede side of the leather and folded in half so that the leather absorbs the paste. This process is repeated until the leather is fully saturated with adhesive.

Edge paring the leather with a razor sharp knife. Paring essentially bevels the leather around its perimeter, allowing it to be easily turned in around the board edges of the book.

To cover, the leather is first carefully worked over the spine and smoothed over the outside of the boards. Next, the excess leather is turned in over the board edges and around the spine, with special attention given to the corners and caps. If the book has raised cords, it is 'tied up' in a press to ensure even bonding between the leather and the spine. The freshly covered book is then nipped in the press for an hour and left to dry between boards and under weight.

After the leather dries it is time for decoration. Depending on the desired result, the leather is sprinkled, tooled (with darkened impressions, referred to as 'in blind', or with gold leaf), and polished. If previously commissioned, personalization happens here too.

Three newly covered commonplace books. The pages are wrapped to protect the edges during covering.

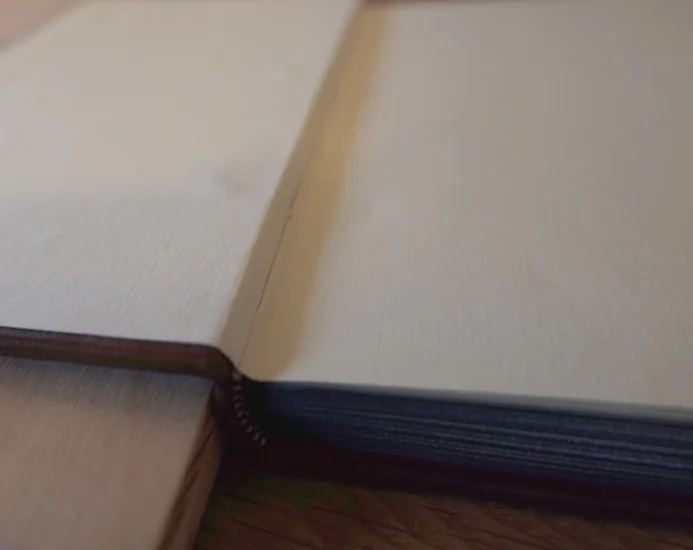

The outermost page is pasted and laid down over the inside of the cover.

Finally, the covers are gently opened up and the first and last pages (referred to as paste downs) of the book are pasted out one at a time and laid down over the inside of the cover. When dry enough, the covers are closed, and the book is set under light weight overnight.

Once dry, the volume is gently broken in to prepare it for daily use, resulting in a finished book that is anything but commonplace.

Though structurally nearly identical, each cover is a blank slate offering a limitless variety of decorative possibilities.